Qalabka & Qaybaha Mashiinada Beeraha

Birta aan la taaban karin: SS304, SS304L, SS316, SS316L, SS303, SS630

Birta kaarboon: 35CrMo, 42CrMo, ST-52, Ck45, birta daawaha;ST-37, S235JR, C20, C45, 1213, 12L14 birta kaarboon;

Birta la shubay: GS52

Birta la tuuray: GG20, GG40, GGG40, GGG60

Alaabta naxaasta ah: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminium aluminium: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

Caaga: DERLIN, nylon, Teflon, POM, PMMA, PEEK, PTFE

Mashiinnada beeruhu waxay la xiriiraan qaab-dhismeedka farsamada iyo aaladaha loo isticmaalo beeraha ama beeraha kale.Waxaa jira noocyo badan oo ka mid ah qalabkan, laga bilaabo qalabka gacanta iyo qalabka korontada ilaa cagafyada iyo noocyada aan la tirin karin ee qalabka beeraha ee ay jiidaan ama shaqeeyaan.Qalab kala duwan ayaa loo isticmaalaa beeralayda organic iyo kuwa aan dabiiciga ahayn labadaba.Gaar ahaan tan iyo markii ay abuurmeen beero makaanaysan, makiinadaha beeruhu waa qayb aan laga maarmi karin sida adduunka loo quudiyo.

Imaatinkii Kacaankii Warshadaha iyo horumarinta mishiinada adag, hababka beeralaydu waxay qaadeen horumar weyn.[1] Halkii ay ku goosan lahaayeen hadhuudh gacanta leh daab af leh, mashiinnada taayirrada leh ayaa gooyay qulqul joogto ah.Halkii ay hadhuudhkii ku garaaci lahaayeen ulo, mishiinnada wax lagu tumo ayaa ka soo saaray iniinaha madaxa iyo cawska.Cagafyadii ugu horreeyay waxay soo shaac baxeen dabayaaqadii qarnigii 19-aad.

Awoodda mishiinada beeraha waxaa markii hore keeni jiray dibi ama xoolo kale oo la dhaqdo.Markii la ikhtiraacay tamarta uumiga waxaa yimid matoorka la qaadi karo, ka dibna matoorka jiidashada, ujeedo badan, isha tamarta wareega oo ahayd ina-adeerkii dhulka gurguurta ee maraqa uumiga.Matoorada uumiga beeralayda ayaa la wareegay shaqada culus ee jiidista dibida, waxaana sidoo kale lagu rakibay jiidh awood u leh mishiinada taagan iyadoo la isticmaalayo suun dheer.Mashiinnada uumiga ku shaqeeya waxay ahaayeen kuwo hooseeya marka loo eego heerarka maanta, laakiin, cabbirkooda iyo saamiga geeradooda hoose awgeed, waxay bixin karaan jiid jiid weyn.Xawaarahooda gaabis ah ayaa beeralayda u horseeday in ay ka faalloodaan in cagaf-cagaftu ay lahaayeen laba xawli: " gaabis ah, iyo damn gaabis ah."

Matoorka gubashada gudaha;marka hore mishiinka shidaalka, ka dibna matoorada naaftada;waxay noqotay isha ugu wayn ee cagafyada soo socda.Matooradani waxa kale oo ay ka qaybqaateen horumarinta is-xakamaynta, gooya iyo tumayaha, ama isku-darka (sidoo kale loo soo gaabiyo 'isku-darka').Halkii ay ka jari lahaayeen caws hadhuudh ah oo ay u qaadi lahaayeen mishiin taagan oo wax lagu tumo, kuwaas waxa ay isugu geeyaan jar, tuntaan, oo kala saaraan hadhuudhka iyagoo si joogto ah u dhex socda beerta.

Isku-darka ayaa laga yaabaa in ay shaqada goosashada ka fogeeyeen cagaf-cagafyada, laakiin cagaf-cagafyadu wali waxay qabtaan shaqada ugu badan ee beerta casriga ah.Waxa loo isticmaalaa in lagu riixo/jiida qalabyada—mashiinada dhulka beera, abuura abuur, oo qabta hawlo kale.

Qalabka beerista waxay u diyaariyaan carrada beerashada iyagoo debcinaya ciidda oo dila haramaha ama dhirta tartamaya.Kan ugu caansan waa xaaqidda, qalabkii qadiimiga ahaa ee la cusboonaysiiyay 1838-kii John Deere.Xashiishka ayaa hadda si ka yar Maraykanka looga isticmaalo sidii hore, iyada oo saxanadaha loo isticmaalo beddelka ciidda, iyo jeexjeexyada loo isticmaalo in lagu helo qoto dheer oo loo baahan yahay si loo ilaaliyo qoyaanka.

Nooca ugu caansan ee abuuraha waxaa loo yaqaannaa beeralay, wuxuuna u baneeyaa iniinaha si siman oo saf dheer ah, kuwaas oo inta badan u dhexeeya laba ilaa saddex cagood.Dalagyada qaar waxa lagu beeraa layli, kuwaas oo soo saaray iniin aad uga badan oo safaf ka yar cag isu jira, oo beerta ku daboola dalagyada.Transplanters ayaa si otomaatig ah u ah hawsha beerista geedo beerta.Iyadoo si baahsan loo isticmaalo mulch caag ah, lakabyada mulch caag ah, beeralayda, iyo seederyadu waxay dejiyaan safaf dhaadheer oo caag ah, oo si toos ah ugu dhex beero.

Beeritaanka ka dib, mishiinada kale ee beeraha sida buufinta iskood u shaqeysta ayaa loo isticmaali karaa bacriminta iyo sunta cayayaanka.Codsiga buufinta beeraha waa hab looga ilaaliyo dalagyada haramaha iyadoo la adeegsanayo herbicides, fungicides, iyo cayayaanka.Buufinta ama beeridda dalagga daboolka ah ayaa ah siyaabo lagu qaso koritaanka haramaha.

Beerista dalagyada Xayawaanka ayaa loo isticmaali karaa in si adag loo baakado cawska ama alfalfa loona sameeyo qaab la kaydin karo bilaha jiilaalka.Waraabka casriga ahi waxa uu ku tiirsan yahay mishiinada.Matoorada, matoorada iyo qalabka kale ee khaaska ah ayaa si degdeg ah oo aad u sarreeya biyaha u siinaya dhul ballaaran.Noocyada la midka ah ee qalabka sida buufinta beeraha ayaa loo isticmaali karaa in lagu keeno bacriminta iyo sunta cayayaanka.

Cagafyada ka sokow, waxaa loo diyaariyey gaadiid kale oo loo isticmaali karo beeraha, kuwaasoo ay ka mid yihiin kuwa xamuulka qaada, diyaaradaha iyo helikobtarada, sida kuwa lagu daabulo dalagyada iyo samaynta qalabka guurguura, si loogu buufiyo hawada iyo maamulka xoolaha nool.

Qaybaha Bush oo leh daawaynta madow

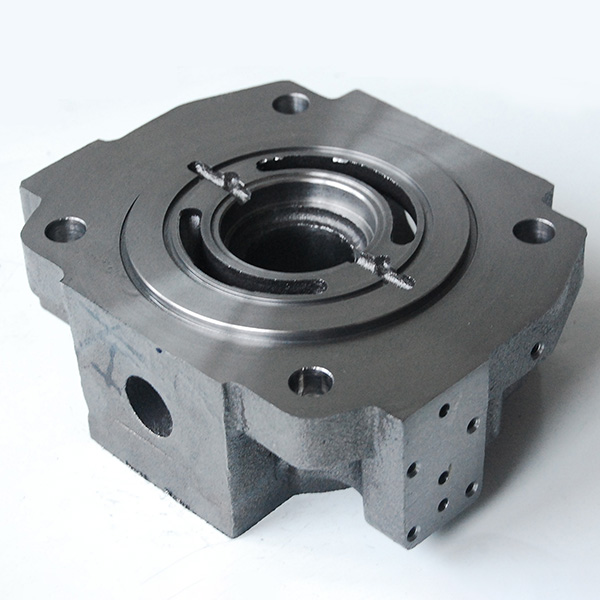

shubista birta kaarboon

Qaybaha shubka birta kaarboon ee mashiinka dunta